Wastewater Treatment

Learn more about Moulton Niguel’s wastewater treatment facilities and processes.

Moulton Niguel Water District has been providing wastewater collection and treatment services to its customers since 1964. In the late 1960s, the District, in partnership with our local community, was one of the first agencies in the State of California to begin recycling treated wastewater to use for irrigation purposes. Today, recycled water accounts for nearly 25% of the District’s total water demand and directly reduces the amount of drinking water we need to import from the Colorado River or Northern California. The District continues to evaluate opportunities to expand our use of highly treated wastewater to improve local water supply reliability and reduce the amount of treated wastewater discharged to the ocean.

As the region experiences an increasing need for cost-effective and reliable sources of water, the District’s Board of Directors has established goals to identify opportunities to maximize the reuse of water while ensuring cost-effective and reliable wastewater treatment services. As stewards of the environment, the District is focused on ensuring a high-performing wastewater system and reducing the amount of treated wastewater discharged to the ocean. We continue to partner with the County and local cities to develop projects and programs that will reduce unwanted urban runoff into our local creeks and streams by promoting the efficient use of water while exploring the potential to capture urban runoff as an additional water source.

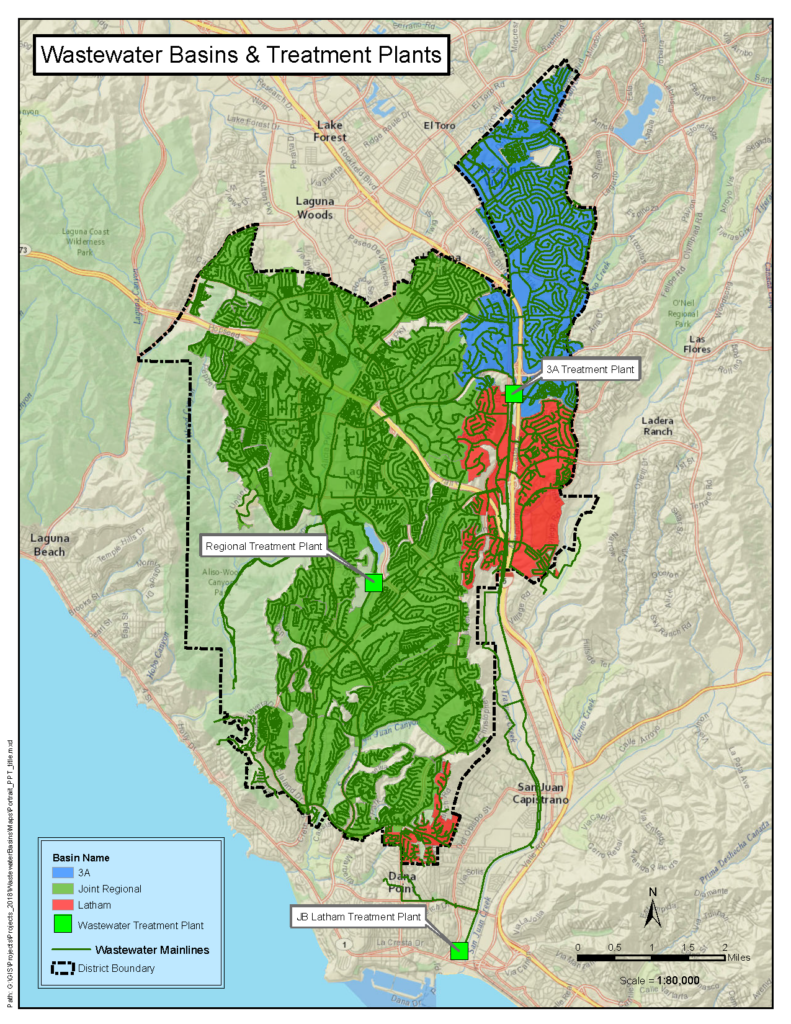

Wastewater Collection and Treatment

Currently, the District collects and treats more than 10 million gallons of wastewater per day from residential and commercial customers throughout our service area. The District utilizes three different treatment plants to appropriately treat the wastewater with two of those treatment plants equipped to produce recycled water. The 3A Treatment Plant in Mission Viejo is owned and operated by the District. The Regional Treatment Plant in Laguna Niguel is currently operated by a regional operator, the South Orange County Wastewater Authority, but is also home to the largest recycled water facility that is owned and operated by the District. Finally, the J.B. Latham Treatment Plant in Dana Point, which is also operated by SOCWA, provides an additional facility for treatment of wastewater. Any treated wastewater that cannot be utilized for irrigation purposes is then discharged to the ocean through one of two ocean outfalls, the Aliso Creek Ocean Outfall and the San Juan Creek Ocean Outfall. The District works closely with SOCWA, as the regional permitting entity, and the appropriate regulatory agencies to ensure that all treated wastewater, whether used for irrigation purposes or discharged to the ocean, is compliant with all regulatory requirements.

3A Treatment Plant

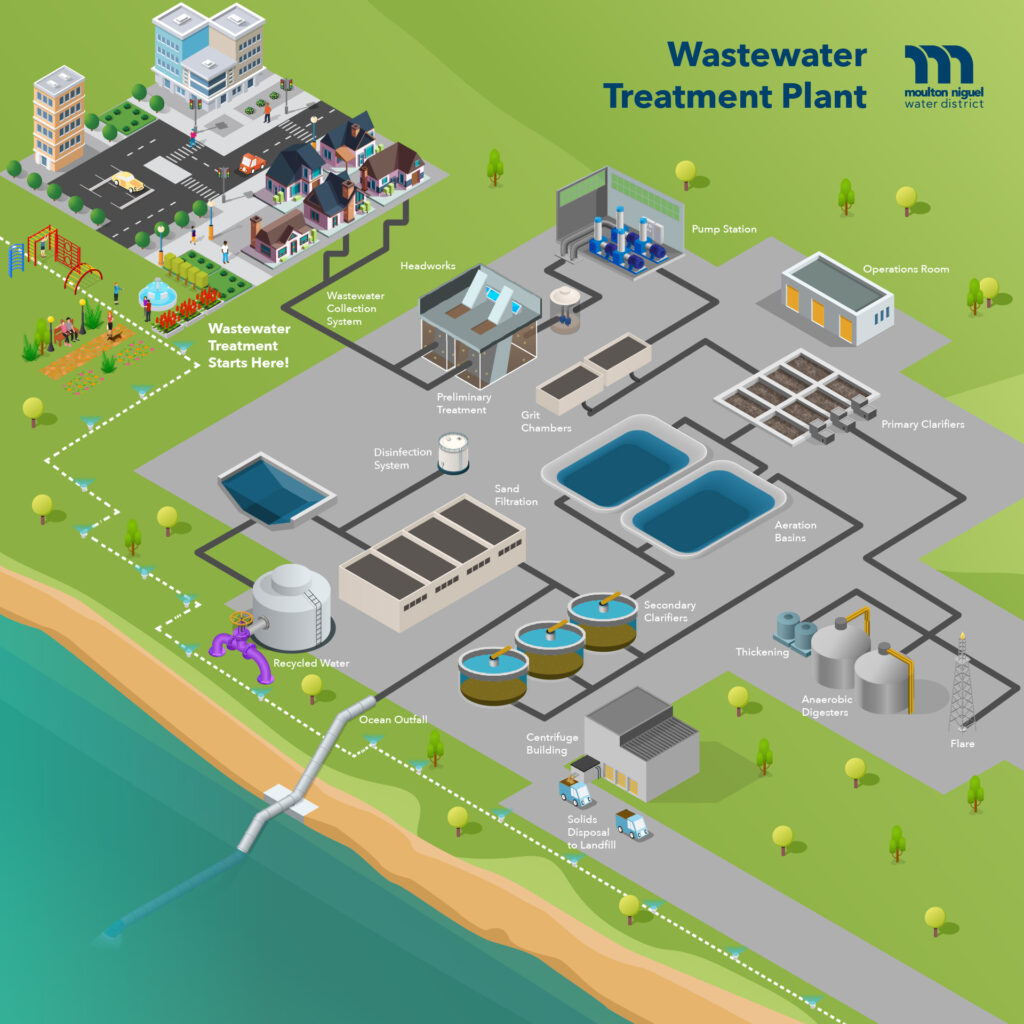

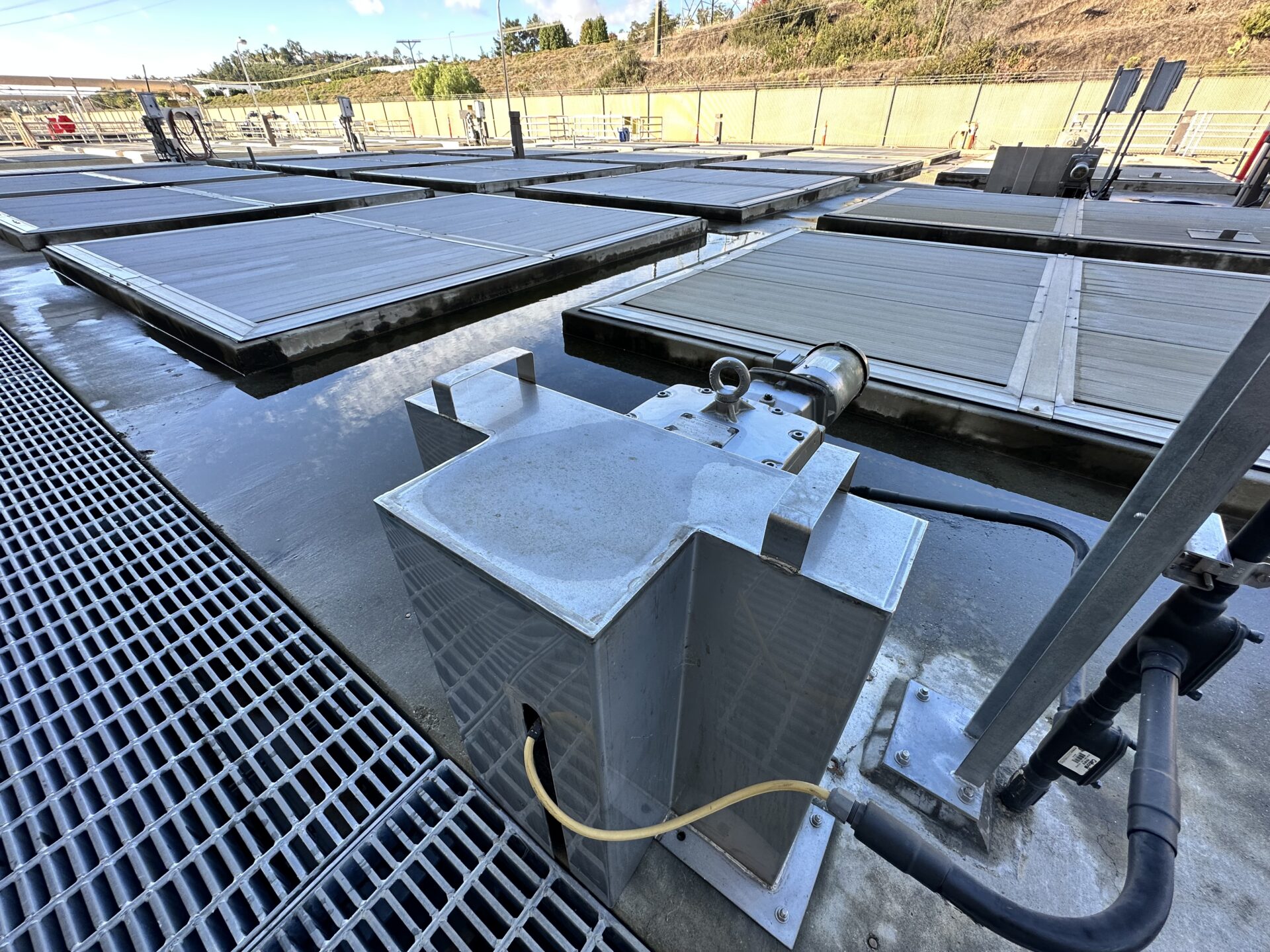

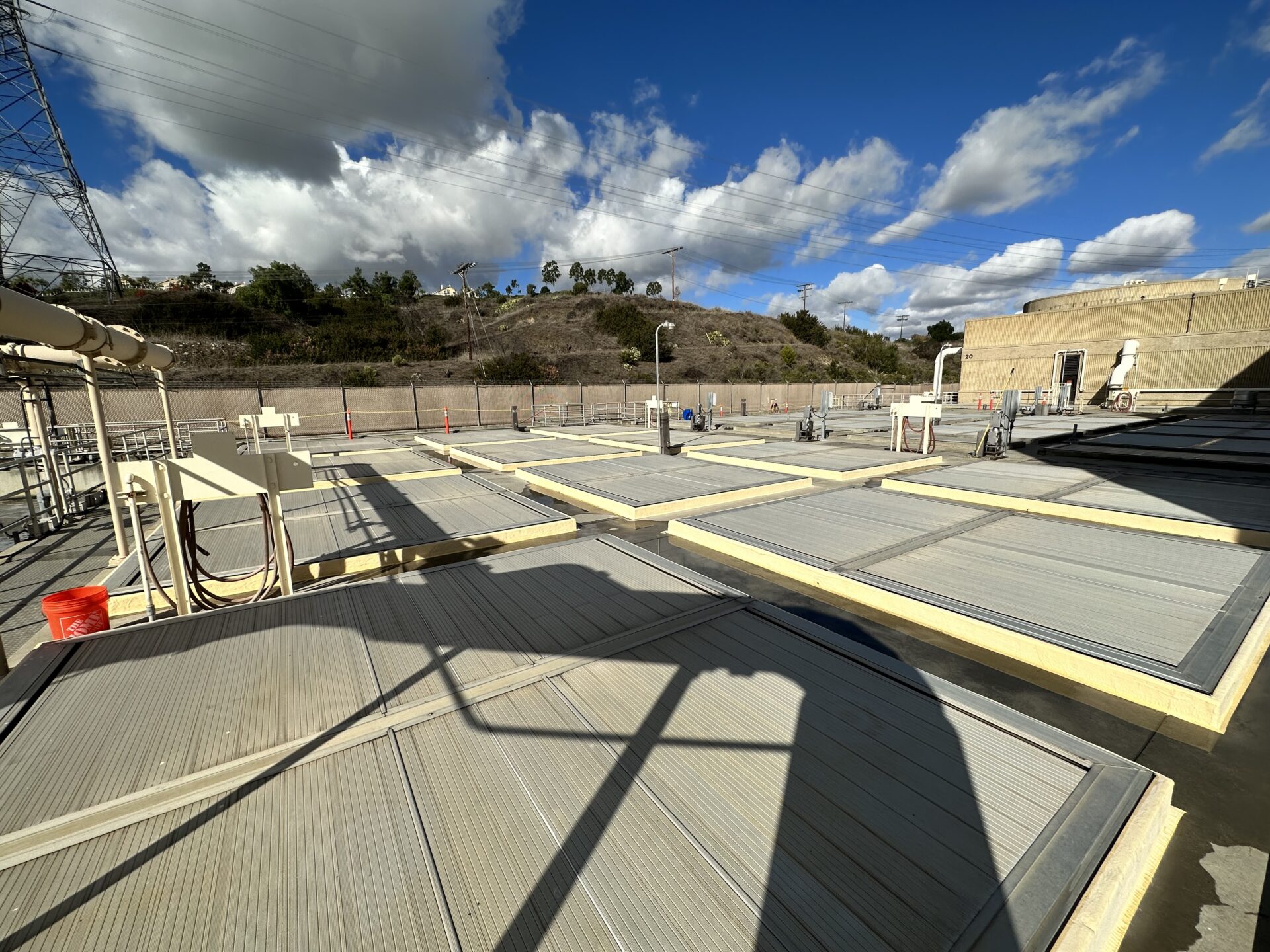

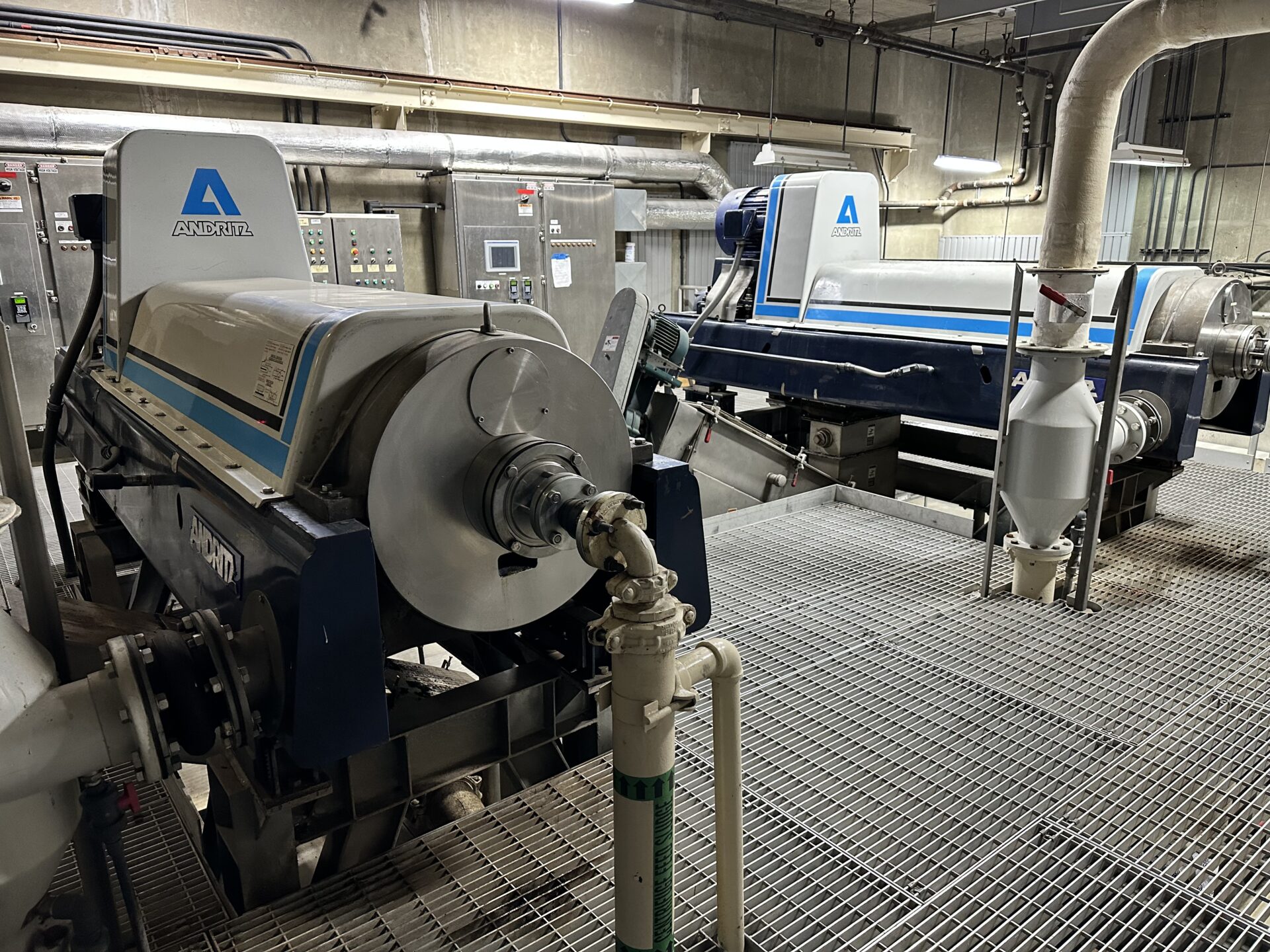

The 3A Treatment Plant is a six million gallons per day (MGD) treatment facility consisting of preliminary, primary, secondary, and tertiary treatment. These core treatment processes produce undisinfected secondary effluent, which is conveyed to the San Juan Creak Ocean Outfall. The plant also has sand media tertiary filters and chlorine disinfection facilities to produce disinfected tertiary recycled water, as defined by Title 22 of the California Code of Regulations. Tertiary-treated effluent is used for irrigation at a local golf course and other landscape areas. Recycled water is stored in the recycled water reservoir system when irrigation demand is low. 3A Treatment Plant’s solids stream includes sludge thickening, anaerobic digestion, and sludge dewatering. Dewatered sludge, also known as “biosolids,” are trucked off site for landfill disposal.

Regional Treatment Plant

The Regional Treatment Plant is located in Laguna Niguel. The total treatment plant capacity is 12 million gallons per day consisting of preliminary treatment, primary treatment, secondary treatment, tertiary filtration, anaerobic digestion and solids dewatering. Dewatered sludge are trucked off site for landfill disposal. Secondary Effluent is discharged to the Aliso Creek Ocean Outfall. Moulton Niguel owns and operates the Advanced Wastewater Treatment facility with a recycled water production capacity of 9.4 million gallons per day.

JB Latham Treatment Plant

The JB Latham Treatment Plant is located in Dana Point. The total treatment capacity is 13 million gallons per day consisting of preliminary treatment, primary treatment, secondary treatment, anaerobic digestion and solids dewatering. Dewatered solids are trucked offsite for landfill disposal. Secondary effluent is discharged to the San Juan Creek Ocean Outfall.

Wastewater Treatment Process